-

Product

-

Fiber laser cutting machine

-

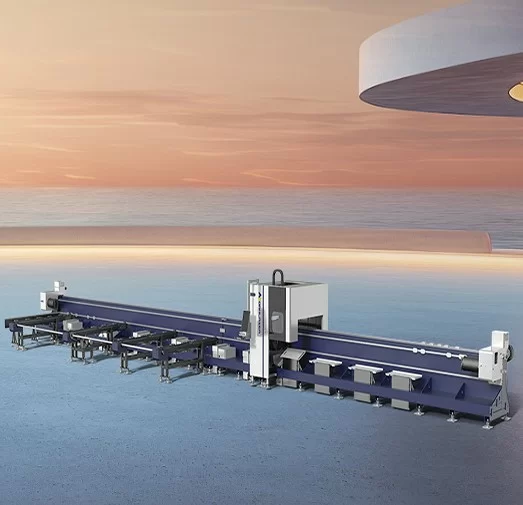

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

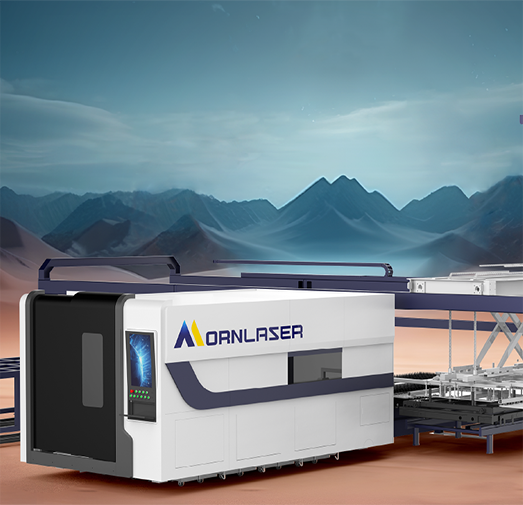

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

Automated laser cutting, empowering you to effortlessly step into the era of smart manufacturing.

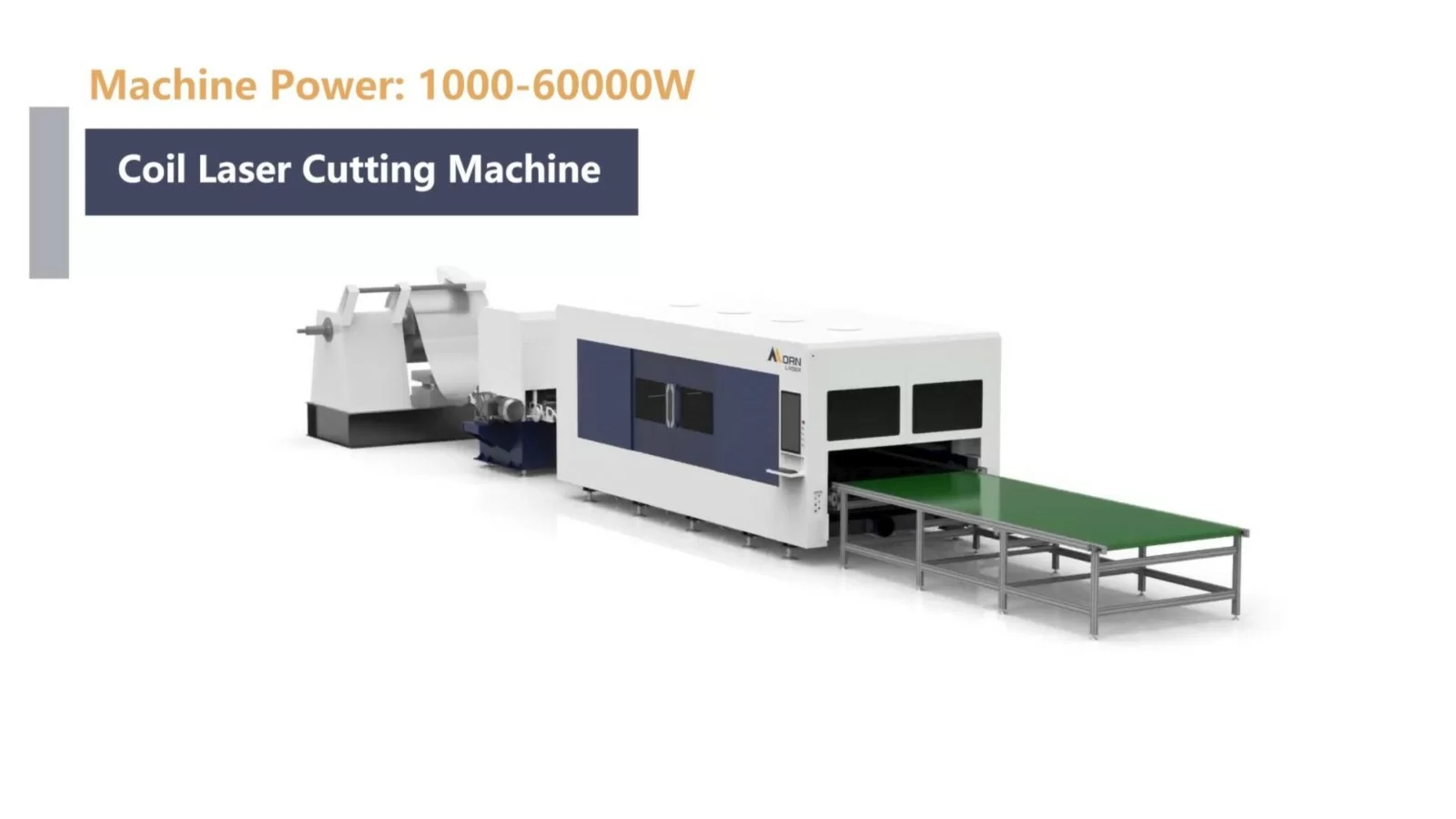

Coil Laser Cutting Machine

1.5GMaximum acceleration140m/minMaximum linkage speed100mmMaximum SS cutting thickness60000wMaximum laser power![Coil Laser Cutting Machine]() Benefits you can get from our Coil Laser Production Line

Benefits you can get from our Coil Laser Production Line![]() High-Level Automation

High-Level Automation![]() Labor Cost Reduction

Labor Cost Reduction![]() Space-saving

Space-saving![]() High Flexibility

High Flexibility![Video Thumbnail]()

![YouTube Logo]()

![]()

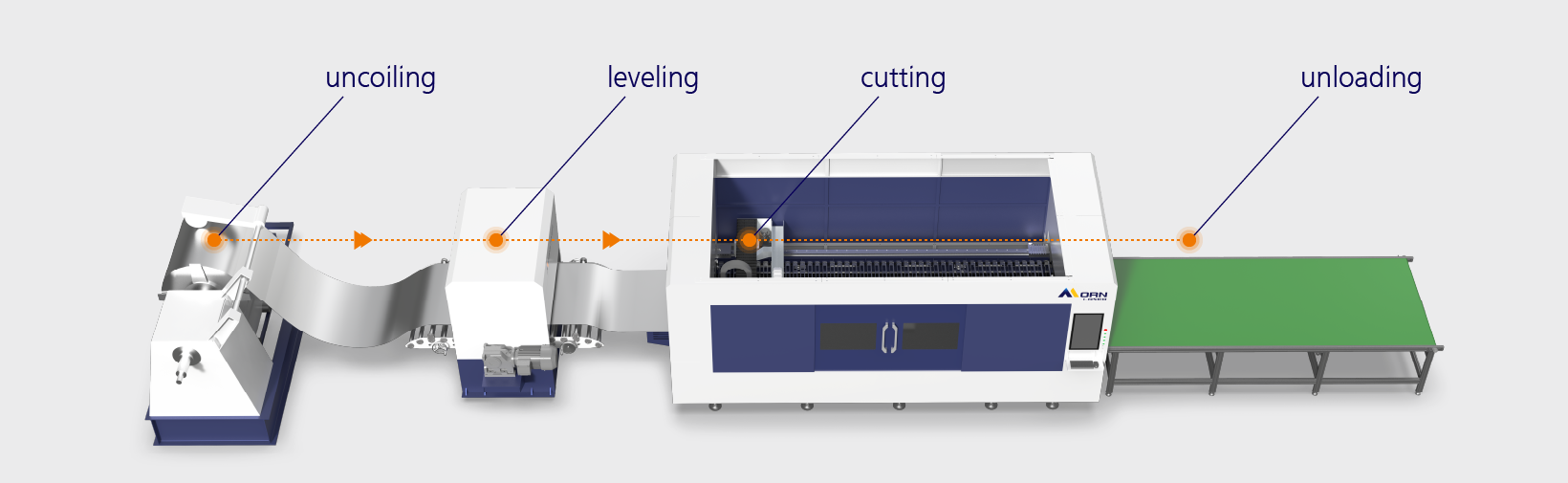

All-in-One-Laser cutting Line:Faster,Smarter Production

Leveling, feeding, cutting, unloading—all in one automated system for seamless, efficient output.

![Laser Cutting]()

Achieve Precision and Efficiency with Laser Cutting

Laser cutting can offer flexible production, one-step forming, no post-processing.

![Laser control system]()

Optimize Production with Intelligent Control System

Our smart cutting system can achieve auto nesting, common-edge cutting, and minimize waste to ensure maximum efficiency.

![Coil Laser Cutting Machine]()

Enhance Automation with Optional Expansion Systems

Customizable smart production systems include film mulching, scrap collection, and automated sorting and palletizing.

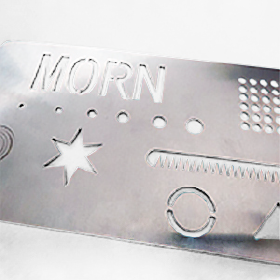

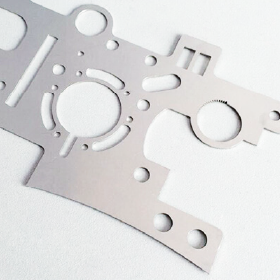

Application & Samples

Favored by metal sheet fabrication factories, automation lines and large fabrication stations, this full cover fiber laser cutting machine fits for mid-thick plate cutting and cuts carbon steel, stainless steel, aluminum, copper, alloy metals effortlessly

![]()

![]()

![]()

![]() Technical Data

Technical DataModel FX-1530 FX-2040 FX-2560 Working Area (Customizable) 3000*1500mm 4000*2000mm 6000*2500mm 12000*2000mm 12000*2500mm Laser Power 2000W/3000W/4000W/6000W/12000W/20000W/30000W/40000W/60000W Repeat Positioning Accuracy ±0.02mm Maximum linkage speed 140m/min Maximum Acceleration Speed 1.5G Power Supply AC380V 50HZ AC220V 60HZ Application & Samples

Favored by metal sheet fabrication factories, automation lines and large fabrication stations, this full cover fiber laser cutting machine fits for mid-thick plate cutting and cuts carbon steel, stainless steel, aluminum, copper, alloy metals effortlessly

![Muestras de corte]()

![Muestras de corte]()

![Muestras de corte]()

![Muestras de corte]()

You may also find these topics interesting

An automated three-dimensional storage tower enables the classification, retrieval, and management of various metals, significantly improving the feeding speed for laser cutting and the overall efficiency of the production line.

Cutting and then unloading takes up valuable time and effort, automate this process with Morn Laser’s exchange table sheet laser cutter and become more efficient! With just an immediate switch, you will keep your production line flowing with no stop.

Three-chuck linkage cutting boosts your tube utilization with virtually no tailings. Three-position tube clamping plus follow-up supports ensure stable tube feeding and prevent long tubes from bending. As a result, you profit from high cutting precision, great efficiency and low material costs.

An automated three-dimensional storage tower enables the classification, retrieval, and management of various metals, significantly improving the feeding speed for laser cutting and the overall efficiency of the production line.

Cutting and then unloading takes up valuable time and effort, automate this process with Morn Laser’s exchange table sheet laser cutter and become more efficient! With just an immediate switch, you will keep your production line flowing with no stop.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote x

Get a Quote

Get a Quote x

![]()